Plastisol Screen Printing T Shirt & Apparel Printing Process

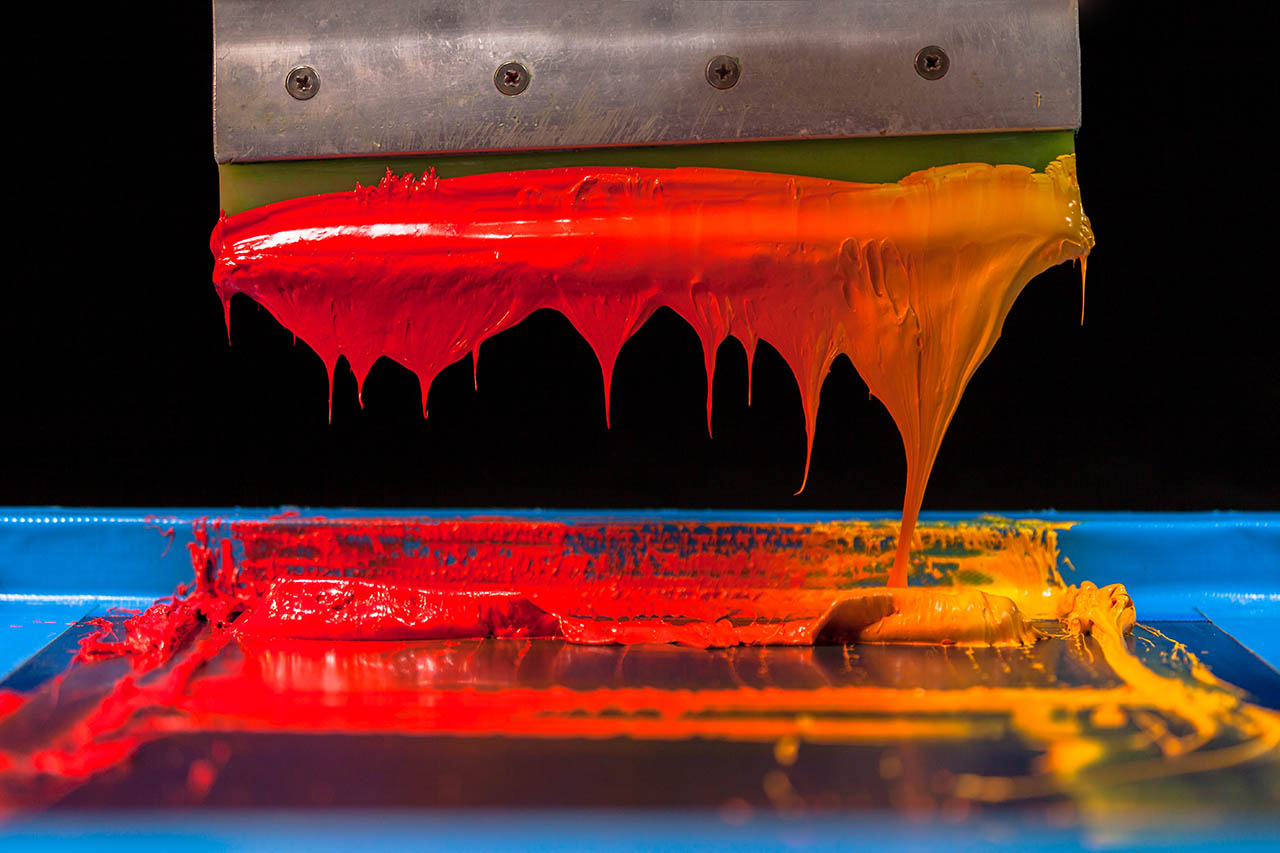

Now plastisol ink has 3 unusual physical prosperities, the first is, plastisol ink is thixotropic, which means as the ink is agitated, stirred or as it is being shuttled forward and back across the screen image by the squeegee, the ink viscosity lowers, making it creamier and easier to print. (Be wary though, if you use electric drill to stir.

How to Use Plastisol Heat Transfers to Print TShirts TShirt Printer

For a bright and clear print, apply your ink, flood the screen and then, pressing down with moderate pressure push or pull the squeegee across the screen. Once the plastisol heat transfer has been created, you'll need to partly cure/ gel the ink. This means heating your plastisol ink between 180- and 240-degrees Fahrenheit.

How To Make Plastisol Screen Print Transfers Simple Guide To Screen

From ink viscosity to curing temperature and mesh selection, let's delve into the science that underpins the art of plastisol printing. Understanding Plastisol Ink. When it comes to the screen printing industry, plastisol ink is a staple. This versatile ink offers a broad range of colors and formulations, making it popular for various applications.

Plastisol Inks Screen printing, Plastisol ink, Prints

You can get soft screen printed t-shirts (even with plastisol ink) but there are a few things you should know first. Let's define a couple of terms: Hand refers to the way a shirt or print feels. "Soft hand" is a way to describe a soft print. Plastisol is the most common type of screen printing ink. It's derived from polyvinyl chloride.

HyprPrint Plastisol inktn CMYK Set 4x 1kg Zeefdrukland

Plastisol printing, also known as screen printing, is a popular method used in the textile industry to create vibrant and durable designs on fabrics. This technique involves using a special type of ink that is made from PVC particles suspended in a liquid plasticizer. When heated, the ink cures and forms a solid, flexible layer on the fabric.

5 Reasons Why Plastisol is Still the Best Screen Printing Ink in the

Basically, the printing shop will set up a screen with your design and start printing just like they are printing shirts. Instead of printing on fabric they will print on the hot peel paper. After printing the design onto paper and curing it with a flash dryer, the adhesive powder is applied. The adhesive powder is the key to plastisol heat.

Plastisol Screen Printing T Shirt & Apparel Printing Process

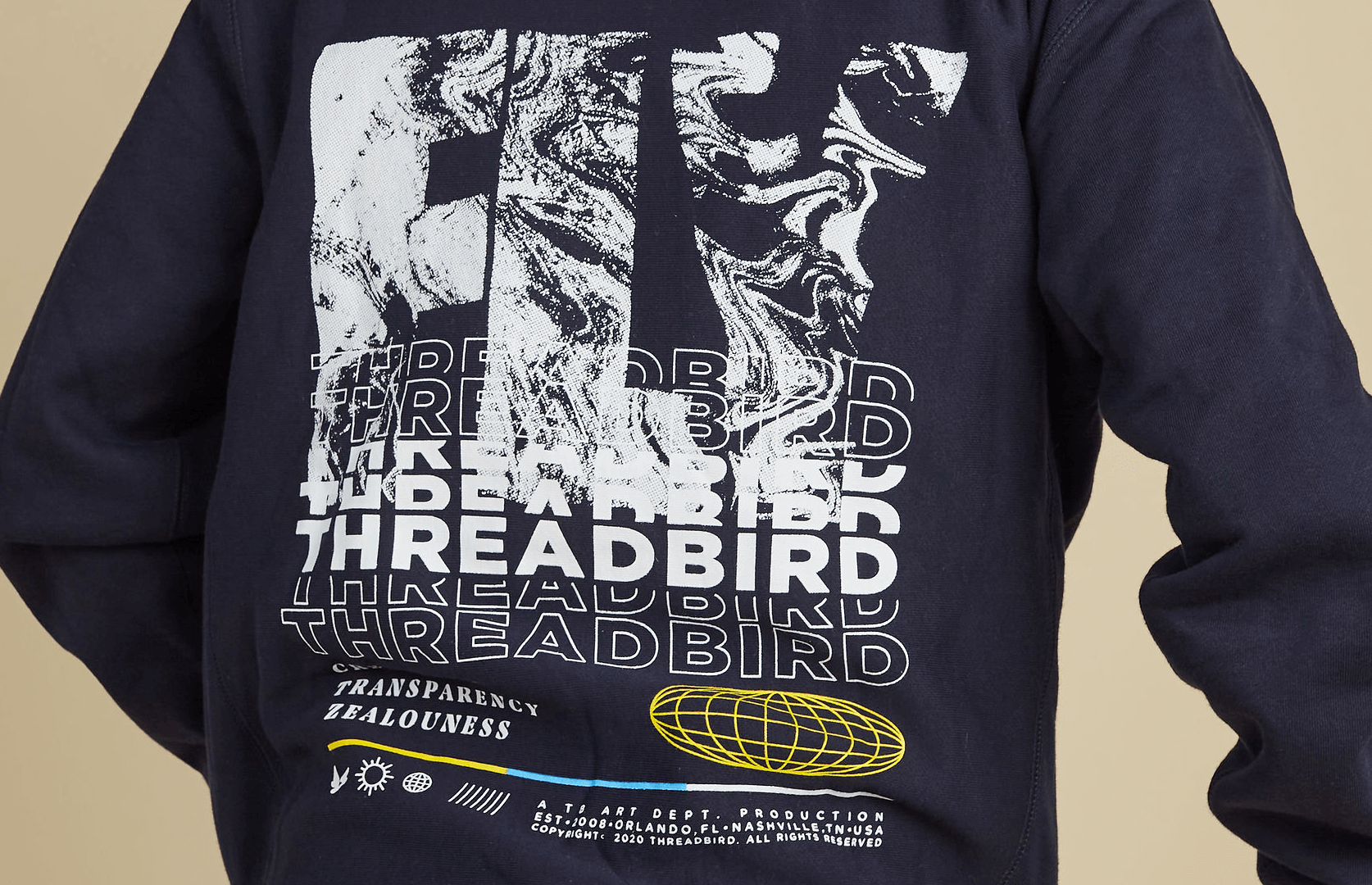

Plastisol screen printing has been the go to choice for apparel designers & manufacturers for the last 4 decades. This type of ink is the most common ink used in screen printing and for good reason. It is vibrant and provides excellent color opacity ensuring your wholesale custom t-shirts is vivid even when printed on dark colored garments.

What Are Plastisol Transfers? Here's What You Need To Know!

Welcome to SEMO Imprints, your source for Custom Screen Printed Transfers. SEMO Imprints has been screen printing custom plastisol heat transfers since 1984. We have always prided ourselves as the least expensive and best choice for Custom Plastisol Heat Transfers. Our loyal customers love knowing the price they see online is the price they pay.

Plastisol Vintage TShirt Textures Vintage tshirts, Vintage graphic

If you own a heat press and print small batches of 5-10 t-shirts at a time, plastisol transfers could be more affordable than taking the screen printing route. Custom made plastisol transfers are usually sold in "gang" sheets - multiple designs screen printed on (typically) an A3-sized transfer sheet - which effectively brings down the.

What are plastisols and how are they made? Oliver + Batlle

Plastisol inks are highly opaque. One of the biggest advantages of plastisol inks is that they can be printed on any color fabric. This is because the ink is so opaque that it will completely cover up the color of the fabric underneath. They can also be printed over dark fabrics and still produce vibrant results.

What is Plastisol Ink? Greek Corner Printing

1st Street Graphics is a leading provider of screen-printed custom heat transfers since 1975. They offer high-quality prints, competitive prices, and excellent customer service specialize in custom plastisol, digital, and simulated process full-color heat transfers for both light and dark-colored fabrics, as well as direct screen printing.

White plastisol ink screen printing Screen printing, Prints, Class

Off-contact distance. Off-contact distance is a complicated variable in plastisol printing as in all other screen-printing applications. The main reason it is included in this list is because of its relationship to screen tension and other variables, including squeegee pressure, squeegee speed, squeegee angle, and even squeegee durometer.

Plastisol Transfer Paper to Florida Flexible Screen

In this video Ryan Moor talks about what plastisol ink is, what the ink has done for screen printing and briefly explains how the ink is used. RELATED PRODUC.

The Untold Benefits of Plastisol Printing

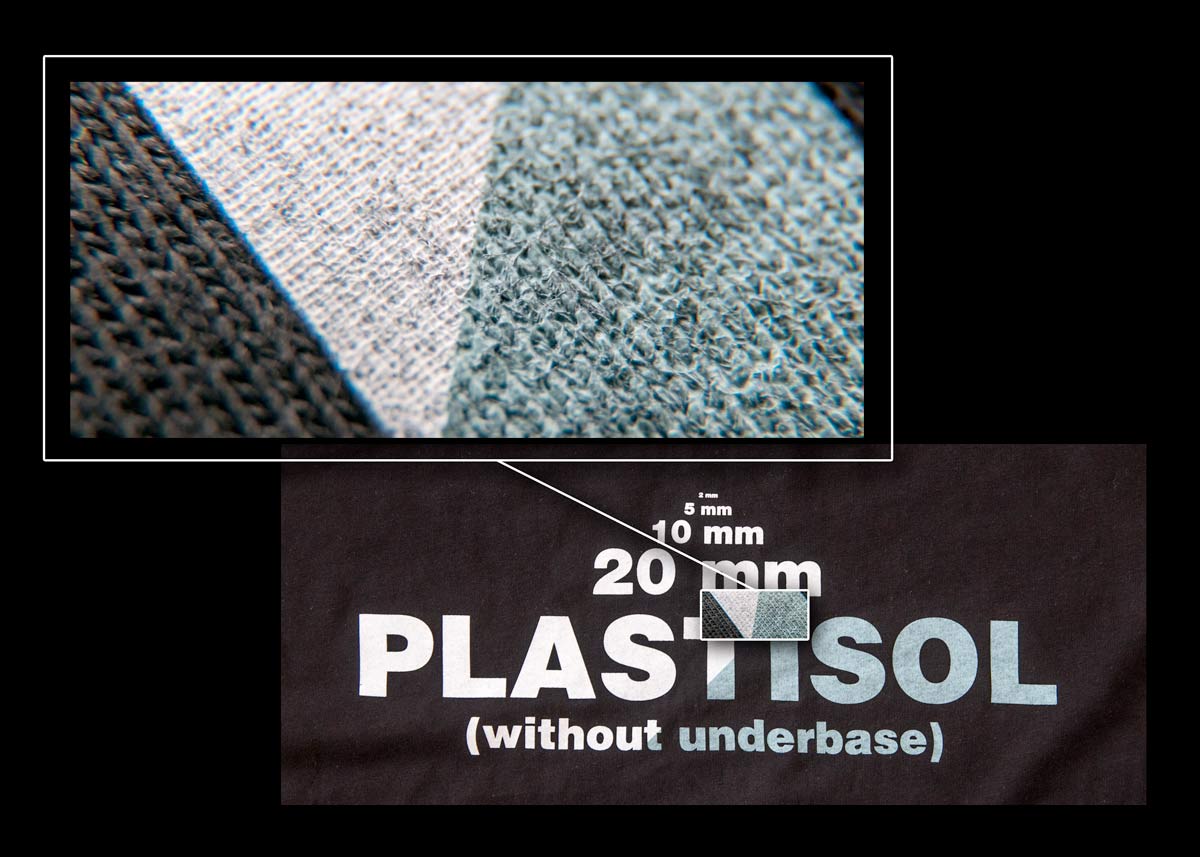

So a Plastisol print is a layer of solidified plastic that sits on top of the fabric. Water-based ink, while not completely free of plastic, is mostly water-soluble and absorbs into the fabric. When this ink is cured, the water-based solvents evaporate, leaving behind only the pigmented binder compounds- less of an ink deposit than Plastisol..

High Build plastisol print Contract Screen Printer and t shirt printing

Apparel Printing: Plastisol ink is widely used in printing designs on t-shirts, hoodies, sweatshirts, and other apparel items. Its durability and resistance to fading and cracking make it an excellent choice for garments that will undergo frequent washing and extended use.

El tejido absorbe el plastisol. ¿Cómo se resuelve? CPL Fabbrika

Plastisol inks are recommended for printing on colored fabric and can retain a bright image for many years with proper care. Most plastisols need to be heated to about 180 degrees celsius (350 Fahrenheit) for full curing. Plastisol printing tends to sit atop the threads instead of soaking into them, giving the print a raised, plasticized texture.